Rolling shear blade series

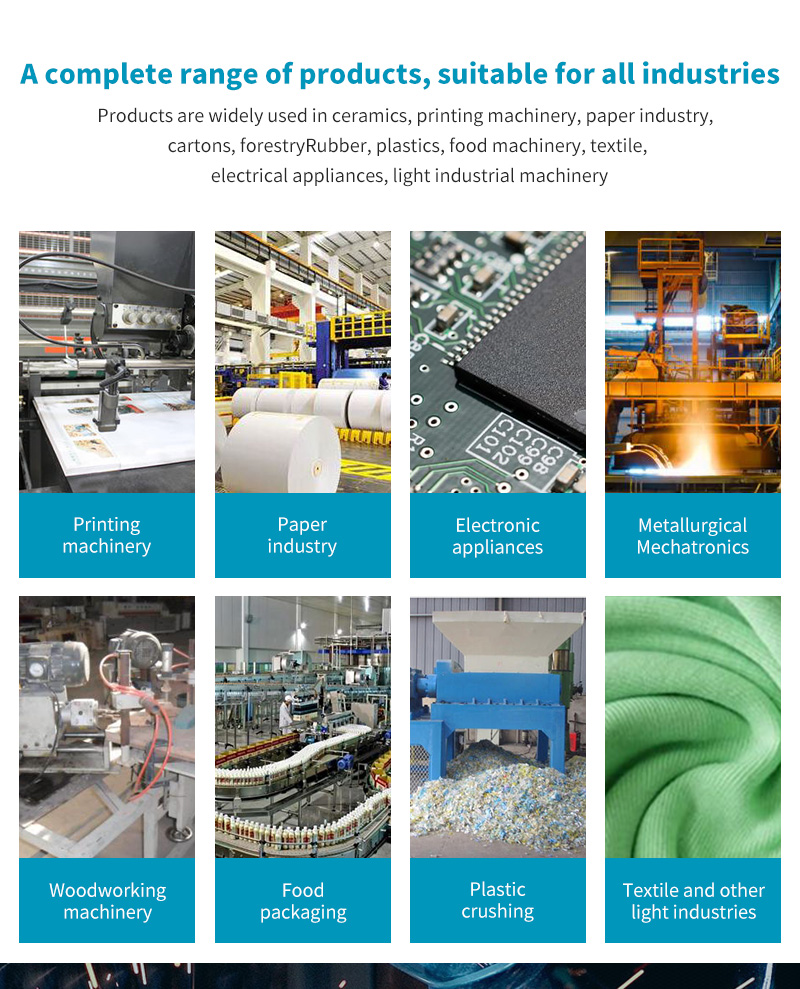

Roll scissors are widely used in paper, paper products processing, tape products, film, wire and cable, rubber, aluminum foil, chemical fiber, non manufactured cloth, composite packaging materials, telecommunication equipment, cigarette, leather, printing, food and clothing industries. The blade is required to have small cutting resistance, high wear resistance and sharp edge of the blade. Due to the accuracy requirements of the product, the edge must be micron precision. In the manufacturing process, the accuracy of the slitting and crosscutting tool holder determines the accuracy of the longitudinal cutting of the product. It can be said that it determines a more effective product quality tool.

Disc rolling scissors are mainly made of T10, 9CrSi, 6CrW2Si, Cr12Mo1V1, h13k, LD, W18Cr4V. The cutting edge is sharp and wear-resistant. It is mainly used for. It can produce all kinds of round scissors blade with diameter less than 1 meter, and high precision circular cutting blade with diameter less than 0.5 meter.

Features of rolling scissors pieces:

The cutting resistance of the blade is small, the wear resistance is large, and the edge is sharp and durable. In order to meet the requirements of commodity precision, the accuracy of tool fixture for slitting and crosscutting determines the accuracy of product incision, which can be said to determine whether the tool is more effective for product quality.

The disc slivers are mainly made of T10, 9CrSi, 6CrW2Si, Cr12Mo1V1, h13k, LD, W18Cr4V, etc. The cutting edge is sharp and wear-resistant. It is mainly used for. It can produce all kinds of round scissors with diameter less than 1 meter and high precision rotary cutting blade with diameter less than 0.5 meters.

- Previous:Rolling shear blade

- Next:Rolling shear blade